Equipment and Product Distribution

Bio Based spray systems LLC, manufactures BIORESTOR® products in house, offering it to dealers, states, counties or agencies. Specialized spray systems designed specifically for the precise application of BIORESTOR® rejuvenators are fabricated for purchase by –

Potential dealers, States DOT departments, Counties, or Agencies with the desire to apply BIORESTOR® asphalt rejuvenators. Please contact Bio Based Spray Systems LLC with any questions involving this process.

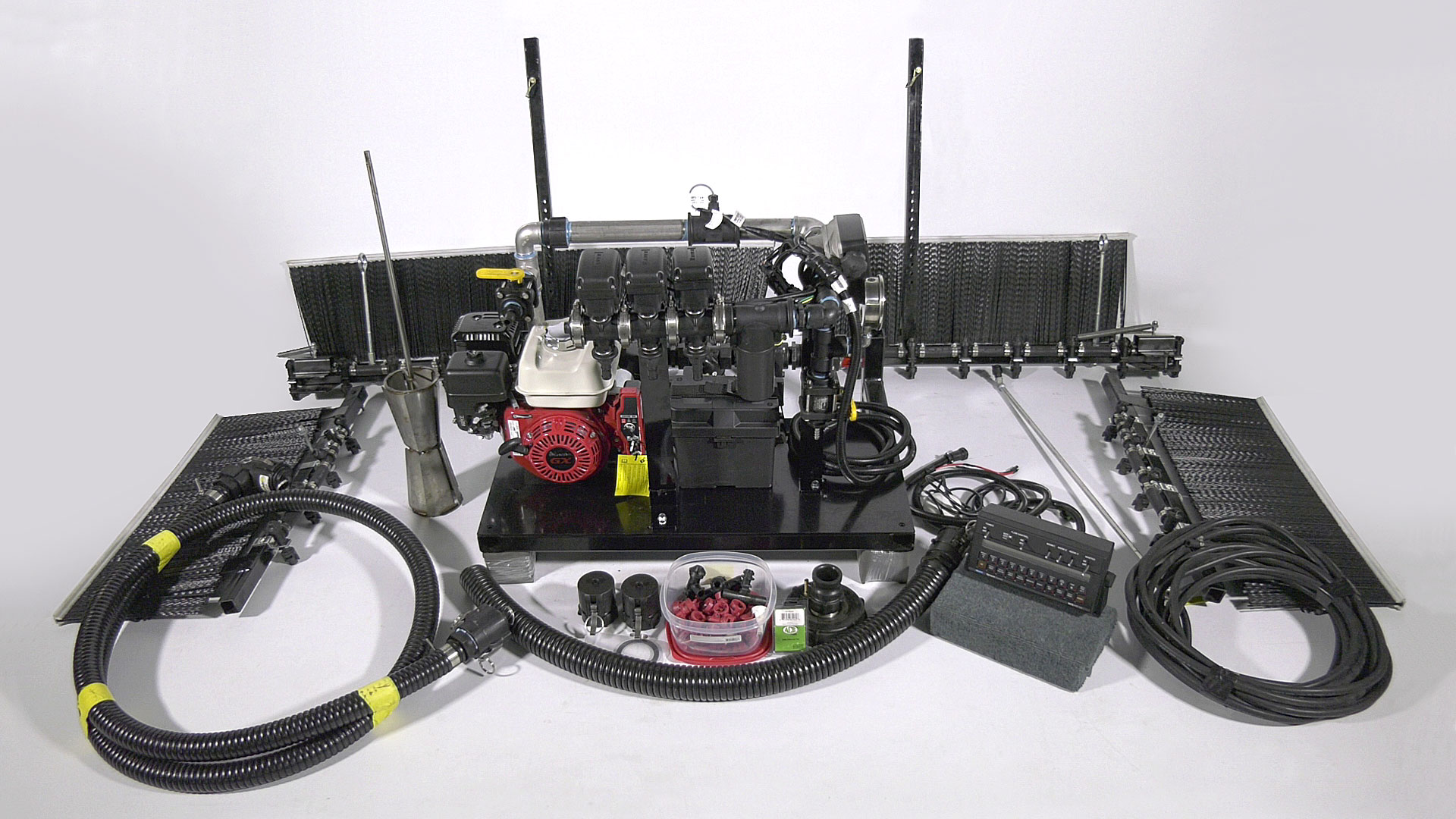

Standard Spray System

- Speed/Pressure is directly related to the application rate, this cost effective, simplicity

model is designed to deliver the product is a constant rate while traveling a constant speed - The system is set up to set a desired driving speed (ex. 5mph) and correlate the constant pressure(ex.50 psi) on the system to deliver the desired rate. Spray tips are carefully chosen to apply the desired amount at the desired pattern for even coverage of the rejuvenator

- 8.5ft spray bar with 2 folding 2ft wings allow for maximum width of 12.5’ and folds to 8.5ft traveling width when not in use. Also wings brake away if any interference were to occur while treating the pavement ( signs, post, mail boxes etc)

Pros of the Speed/Pressure:

- Inexpensive entry cost of system

- Simplicity of rate, speed traveling at pressure of system calculated for desired rate

- One on/off toggle switch in cab runs a valve to apply to product

Cons of Speed/Pressure

- Slightest adjustment in speed effects application rate (±1 mph decreases or increases

application rate by 20% (more or less product going down on the pavement) - Desired spray width (12.5ft max, 10, 8ect.) is solely dependent on tips in the spray bar. Caps must be put in place to “block off” undesired tips of spray. This results in slightly more manual labor when changing spray widths. Example: If you wanted to spray a driveway approaches only before treating an entire road, only possibly 4 tips shall be put in (leaving the rest capped off) and when finished the rest of the tips can be installed. If you only need an 8ft pass on your final spray treatment the curtains are not needed and would require capping off.

- Nothing to monitor volume in tank or constant pressure so some more careful monitoring is needed

- Vehicle Odometer typically does not justify for speedometer gauge, so alternative GPS

monitors must be used such as: IPAD with GPS app, cell phone with app, or alternative sensor capable of displaying 10th mph.

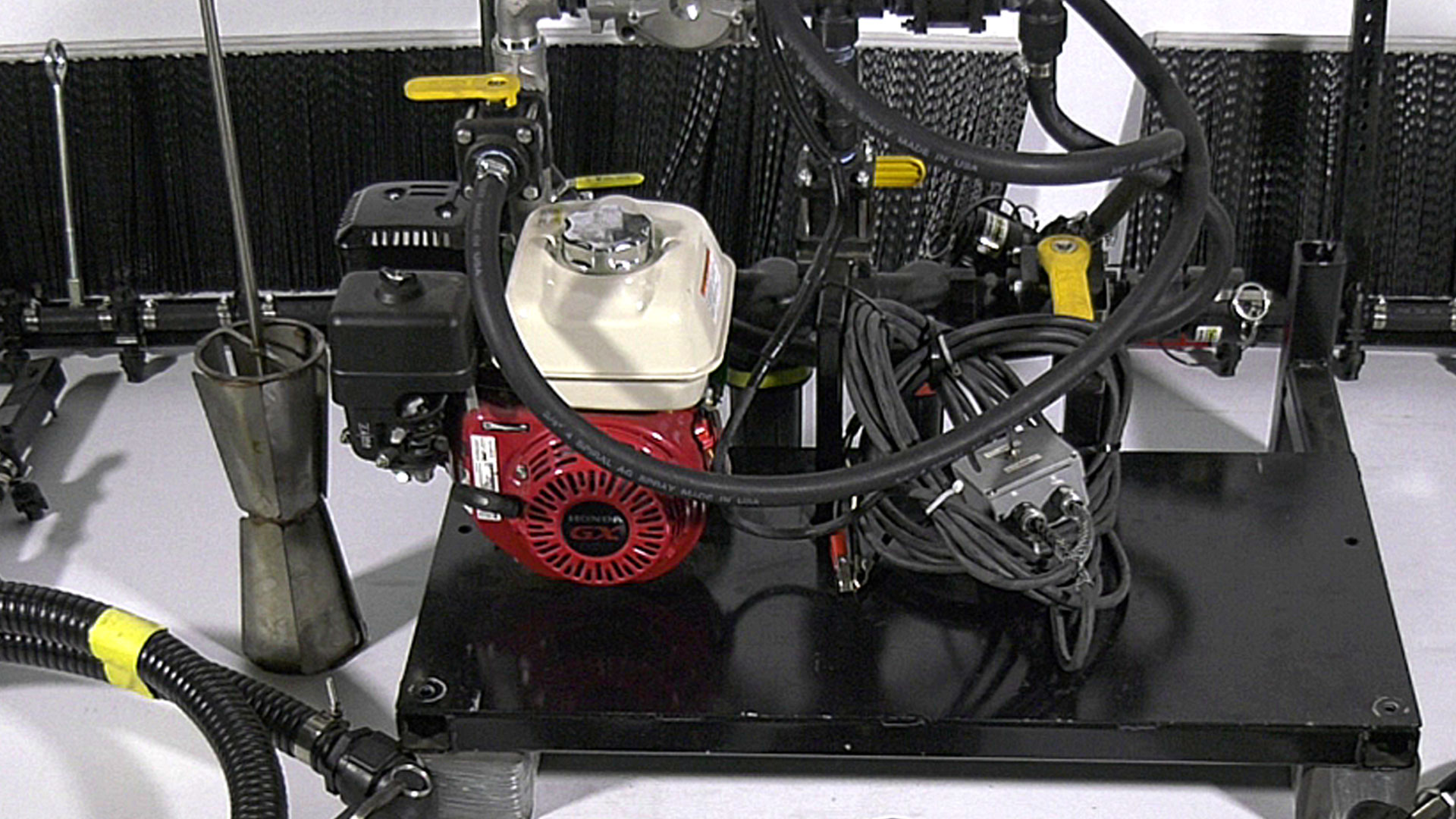

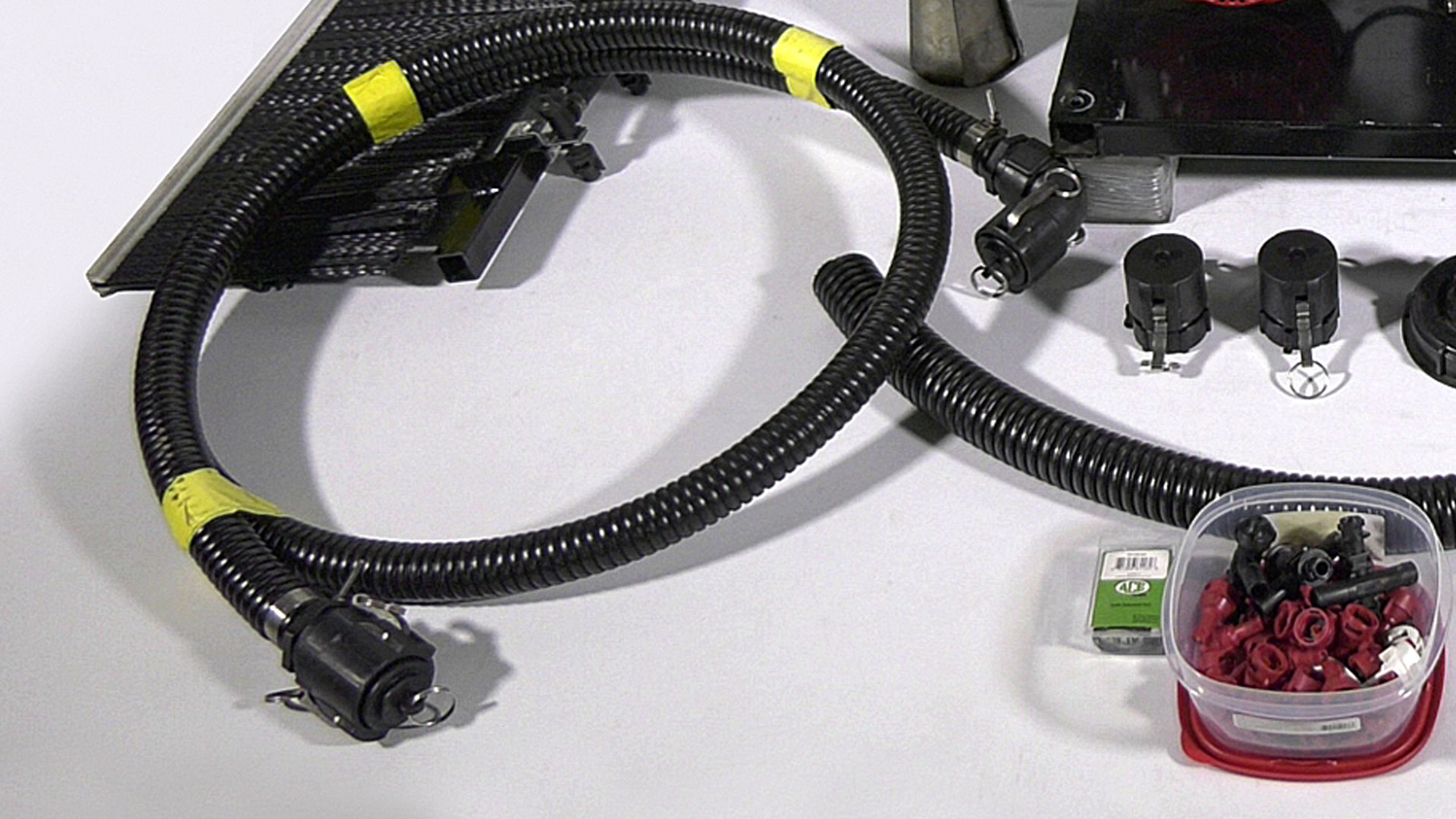

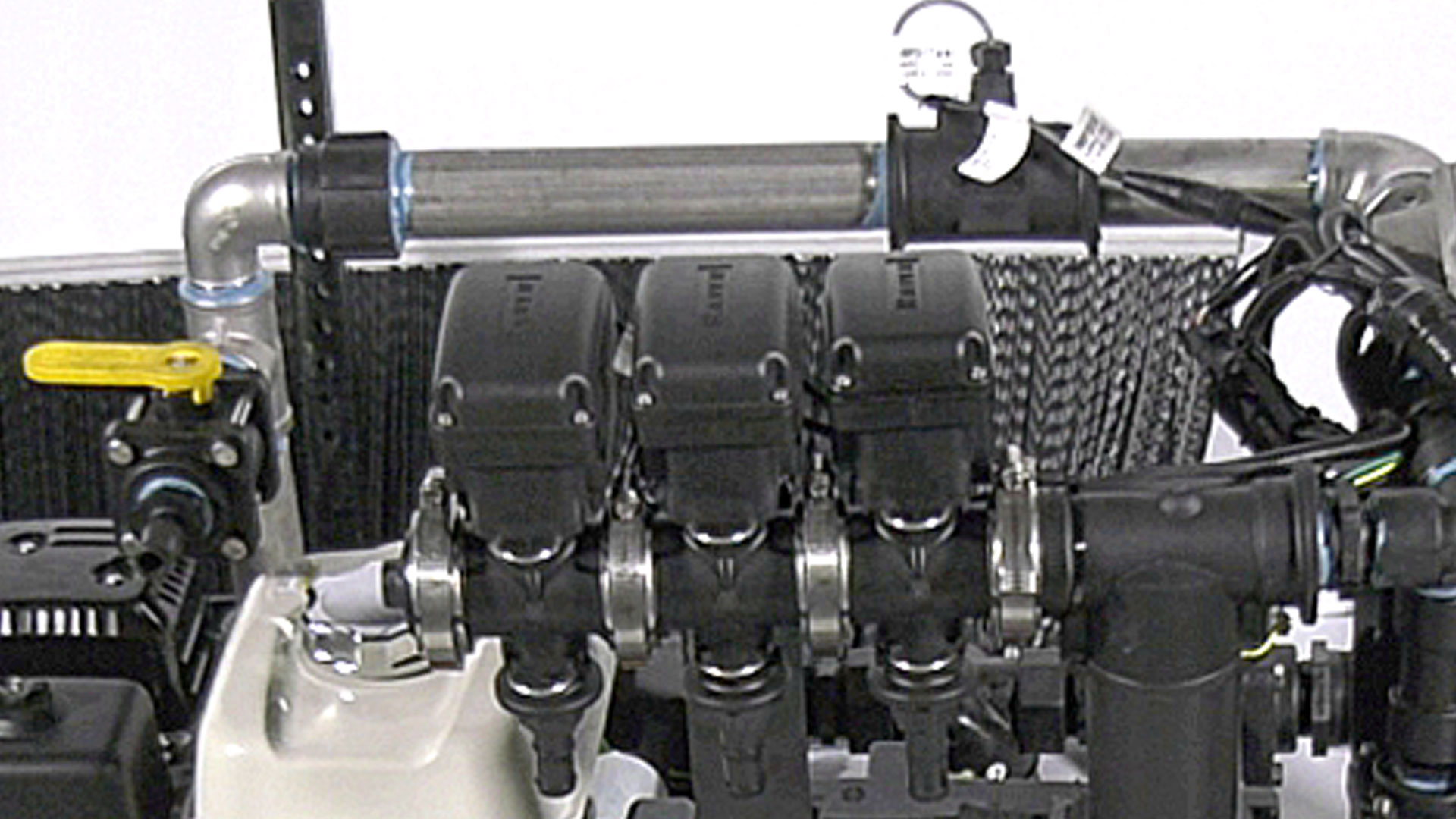

Computerized Spray System

- Spray system embraces an electronic flowmeter coupled with a raven 450 computer console to apply the input application rate.

- Control module is coupled with a GPS system which simultaneously adjust the application rate as speed varies. (within ±1 mph of your desired speed) typically 4-6 mph

- 8.5ft spray bar with 2 folding 2ft wings allow for maximum width of 12.5’ and folds to 8.5ft traveling width when not in use. Also wings brake away if any interference’s were to occur while treating the pavement ( signs, post, mail boxes etc)

Pros of the Computerized Spray System:

- System can correct for slight deviations in speed (±1mph) which helps apply desired rate minimizes over or under application. This feature can easily pay for itself with consistent product application. Not too much/not too little, road is protected but not wasting material

- Control bank has 3 valves allowing for each wing and the center bar to be independently tuned on and off without capping off or inserting nozzles.

- In cab computer can be selected to display multiple functions such as: speed, rate, distance traveled, and gallons used/left in tank.

Cons of the Computerized Spray System:

- Programming initially is more in-depth

- More expensive than simple speed/pressure

Computerized Construction Joint Spray System

- Spray Kit specifically designed for a pick-up truck application 2 ft wide directly to

construction joints or rumple strips. - This system is mounted on an aluminum base with a full cage around it with durability in mind.

- Computerized system uses the same raven 450 control valve as the computerized Truck Mounted Spray System with one bank valve.

- One tote of BIORESTOR at its suggested 0.03 rate on construction joints and rumble strips allow for approx. 7.5 continuous mile of treatment before refilling.

Pros of the Construction Joint Spray System:

- More portable than truck mounted spray systems.

- Narrower spray pattern is perfect for construction joints, rumble strips, and driveway approaches.

- Easily fits into a class III hitch receiver for easy removal.

Cons of the Construction Joint Spray System:

- Not ideal for full road treatment.

- Additional costs of computerized unit

- Programming initially is more in-depth